MTM3 Suspension Slider Magnetostrictive sensor overview:

In ferromagnetic material, the change of magnetization direction will cause the change of dielectric lattice spacing, so that the length and volume of ferromagnetic material change, namely: magnetostriction phenomenon, also known as the Widman effect, and its inverse effect is known as the Villari effect.

The principle of magnetostrictive displacement sensor is to generate a strain pulse signal when two different magnetic fields intersect, and then calculate the time period required for this signal to be detected, so as to calculate the exact position. One comes from a permanent magnet in the ring and the other from an excitation pulse generated by an electronic component in the sensor's electronics chamber. The excitation pulse runs at the speed of sound along a waveguide wire made of magnetostrictive material inside the sensor. When intersecting with the permanent magnetic field in the magnetic ring, the mechanical vibration generated by the waveguide wire forms a strain pulse due to the magnetostriction phenomenon. The strain pulse is quickly detected by a sensing circuit in the electronic chamber. Multiply the total time from the moment the excitation pulse is generated until the strain pulse is detected by a fixed speed of sound, and we can accurately calculate the position change of the magnet. The process is continuous, so every time the position of the ring changes, a new position is quickly measured. Since the output signal is the true position value, rather than a proportional or re-amplified signal, there is no signal drift or change of value, let alone the need to periodically resold as with other sensors.

Magnetostrictive sensor is non-contact, never wear. It has the advantages of high resolution, high precision, high stability, high reliability, fast response time and long working life. Sensors do not need to be re-calibrated or regularly maintained.

Performance parameter

1. Measuring range :30 ~ 3000mm

2. Power supply voltage: +12VDC ~ +24VDC

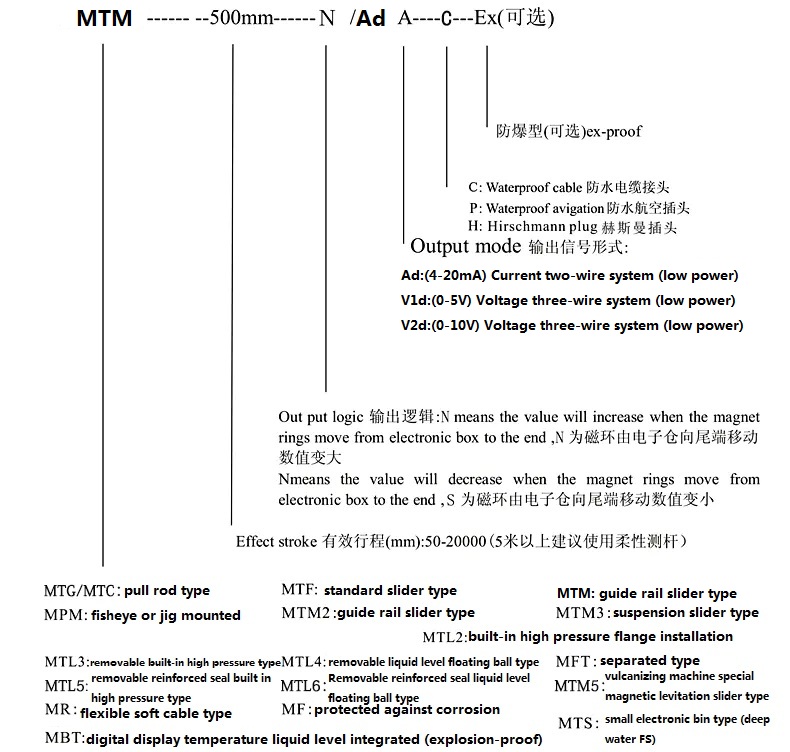

3. Output form/analog signal: current 4-20mA and 0-20mA, voltage 0-5V and 0-10V, digital signal: RS485

4. Load capacity: Voltage signal output load ≥4 KΩ Current signal output load ≤500 Ω

5. Nonlinear error :≤0.05%FS

6. Repeatability error :≤0.0005%FS

7. Resolution :≤0.038mm

8. Hysteresis: acuities were 0.001% FS

9. Temperature stability: ≤0.002%/℃

10. Working current: ≤16mA

11. Operating temperature :T1: -20 ~ +55℃, T2: -40 ~ +80℃, T3: -50 ~ +125℃

12. Rod material: 0Cr18Ni9 (304) 316 stainless steel (special custom)

13. Electronic bin shell material: anodized alumina (special custom)

14. Lead mode: high-temperature resistant twisted-pair shielded cable (default length: 1M, can also be provided according to user requirements)

15. Protection grade of enclosure: IP65

Connection method

Before connecting cables, ensure that the power supply meets the requirement of +24VDC and that the output power of the power supply is greater than or equal to 95mA for each sensor. If the power supply cannot meet the requirements, replace the power supply to ensure the normal operation of the sensor.

Analog signal output wiring mode of MTM Slider magnetostrictive displacement sensor:

1. Connection mode of direct outlet of waterproof connector:

The sensor has five contacts: positive power supply (brown), negative power supply (black), positive signal output (blue), negative signal output (white), shell ground (shielded line)

2. Wiring mode of aviation plug:

The sensor has five contacts: (1) positive power supply (brown), (2) negative power supply (black), (3) positive signal output (blue), (4) negative signal output (white), (5) shell (shielded line)

3. Connection mode of Hersman plug:

The sensor has four contacts: (1) positive power supply (brown), (2) positive signal output (blue), (3) negative power supply (black, white) E, shell ground (shielded line)