Horizontal injection molding machine: This is the most common type of injection molding machine. The clamping part and the injection part are on the same horizontal centerline, and the mold opens horizontally. Its characteristics are: low body, easy to operate and maintain; The center of gravity of the machine is low, and the installation is relatively stable; After the product is ejected, it can be automatically lowered by gravity, making it easy to achieve fully automatic operation. Current injection molding machines typically use fully electronic control, with position sensors used to ensure the optimal position of the slider or template during injection or cooling processes. This helps to improve product quality and reduce experimental error rates. The position sensor is used to measure the position of the injection molding machine slider or template.

The principle of potentiometer is that the precision conductive plastic carbon film resistance displacement sensor (electronic ruler) is the earliest and most widely used displacement sensor in precision injection molding machines due to its low price, simple structure, excellent measurement accuracy and stable performance.

The electronic ruler used in injection molding machines is a high-precision measuring device mainly used to measure the accuracy of mold closing in injection molding machines. Its working principle is to simultaneously measure the distance change during mold closing through high-precision sensors, and convert the change into a number on the display screen. In the production process of injection molding machines, the accuracy of mold closing directly affects product quality and production efficiency. Therefore, the electronic ruler of the injection molding machine can help manufacturers detect and improve the accuracy of mold closing, ensuring the stability of product quality and the improvement of production efficiency.

In addition, the electronic ruler of the injection molding machine can also be linked with the injection molding machine controller to further improve the accuracy of mold closing and production efficiency by automatically adjusting parameters such as mold closing speed and position. This electronic ruler has the advantages of easy digitization, high accuracy, strong anti-interference ability, no human reading error, convenient installation, and reliable use.

In addition to injection molding machines, electronic rulers are also widely used in other mechanical industries such as die-casting machines and rubber machinery. For example, in die-casting machines, due to the harsh operating environment, higher requirements are placed on the waterproof and dustproof performance of electronic rulers, so special customized waterproof electronic rulers need to be used. In rubber machinery, electronic rulers, as part of automation control, achieve precise control of rubber machinery through measurement and positioning.

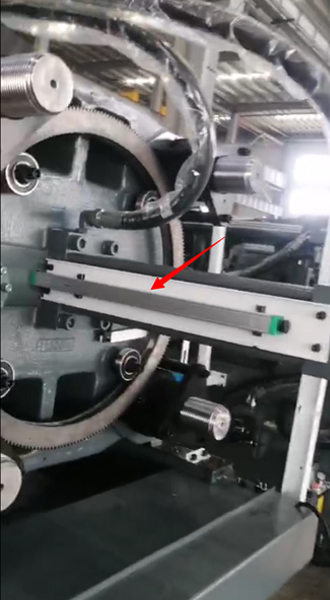

The most commonly used electronic ruler in horizontal injection molding machines is the pull rod electronic ruler, also known as a linear displacement sensor, which plays an important role in injection molding machines. This type of sensor is mainly used to measure displacement and position in injection molding machines, thereby achieving precise control of the injection molding process.

Firstly, the range of the pull rod electronic ruler is generally between 50-1250mm, and its accuracy and resolution are quite high, which can meet the requirements of displacement measurement for injection molding machines. Sensors operate based on the principle of potentiometers and output DC voltage signals, which can be further converted into standard analog signals (such as 0-5V, 0-10V, 4-20mA) or RS485 signals, making data easier to process and transmit.

Secondly, due to the fact that the pull rod electronic ruler can have built-in or external transmission modules, it can transmit the measured displacement data in real-time to the control system of the injection molding machine. The control system adjusts the operating status of the injection molding machine based on this data, thereby achieving precise control of the injection molding process.

Finally, the pull rod electronic ruler is suitable for various automated mechanical equipment, including but not limited to injection molding machines, die-casting machines, rubber machines, woodworking machinery, etc. They are responsible for measuring and positioning within these devices, ensuring their normal operation and stable product quality.

Overall, the application of pull rod electronic rulers in injection molding machines is mainly to achieve precise displacement measurement and position positioning, thereby ensuring the stability of the injection molding process and the consistency of product quality.