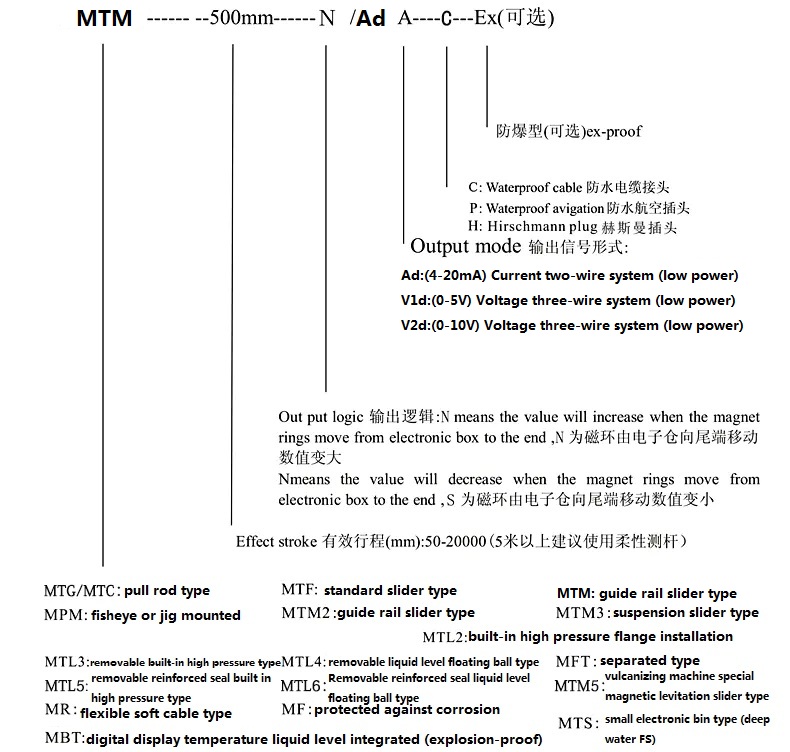

MTM Low power Guide Slider Magnetostrictive Displacement sensor Overview:

The change in the direction of magnetization in the ferromagnetic material will cause the change in the lattice spacing of the medium, so that the length and volume of the ferromagnetic material will change, that is, the magnetostriction phenomenon, also known as the Wiederman effect, and its inverse effect is called the Villari effect.

The principle of magnetostrictive displacement sensor is to generate a strain pulse signal when two different magnetic fields intersect, and then calculate the time period required for this signal to be detected, so as to convert the accurate position. The two magnetic fields, one from the permanent magnet in the magnetic ring, and the other from the excitation pulse generated by the electronic components in the sensor's electronic compartment. The excitation pulse travels at the speed of sound along a waveguide filament made of magnetostrictive material inside the sensor. When intersecting with the permanent magnet field in the magnetic ring, the mechanical vibration generated by the waveguide wire forms a strain pulse due to magnetostriction. The strain pulse is quickly detected by a sensing circuit in the electronic chamber. From the moment when the

excitation pulse is generated to the total time when the strain pulse is detected by a fixed sound speed, we can accurately calculate the position change of the magnet. This process is continuous, so whenever the position of the magnetic ring changes, the new position is quickly measured. Since the output signal is a true position value, rather than a proportional or reamplified signal, there is no signal drift or variation, let alone the need to periodically re-label as with other sensors.

Magnetostrictive sensors are non-contact and never wear out. It has the advantages of high resolution, high precision, high stability, high reliability, fast response time and long working life. Sensors do not need to be re-calibrated or regularly maintained.

MTM low power guide slide type magnetostrictive displacement sensor Technical parameters:

★ Measuring range: 50 ~ 5000mm

★ Power supply voltage: +13VDC ~ +26.5VDC

★ Output signal: two-wire current 4-20mADC (low power consumption)

★ Load capacity: current signal output load ≤500Ω

★ Linear accuracy: ±1mm

★ Resolution :1mm

★ Hysteresis: better than 0.002%FS

★ Operating temperature: -40℃ ~ +85℃

★ Lead mode: PVC shielded cable (default length: 1m, can also be provided according to user requirements)

★ Enclosure protection grade: IP65

MTM low power guide slide type magnetostrictive displacement sensor wiring:

Waterproof connector direct cable connection: power supply (brown), 4-20mA output (blue), housing ground (shielded wire)

Aviation plug wiring: ① power supply (brown), ②4-20mA output (blue), ③ shell ground (shielded wire)

MTM Low power guide slide type magnetostrictive displacement sensor Applications:

Servo hydraulic cylinder piston position preset and feedback, servo cylinder piston position preset and feedback, grinding machinery position preset and feedback, casting and forging machine position preset and feedback, other machinery such as gantry machine position preset and feedback, boring machine, shield machine, coal mine mechanical cylinder position preset and feedback, engineering lifting mechanical cylinder position preset and feedback, Position presetting and feedback of mechanical cylinder in steel mills such as rolling mills, position presetting and feedback of oil cylinder in blow molding, position presetting and feedback of injection molding machinery, adjustment of railway and bridge, detection of water level, control of sluice gates, position presetting and feedback of wood machinery, position presetting and feedback of cylinder level, position presetting and feedback of chemical container level, drinking water and sewage treatment system, Geodetic system, gate opening position preset and feedback, cylinder level measurement

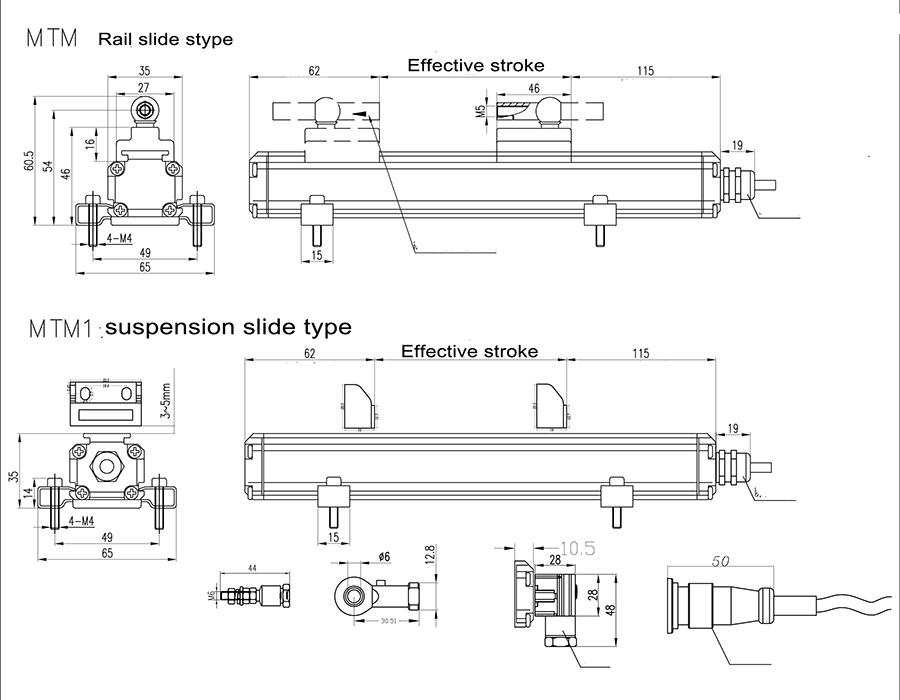

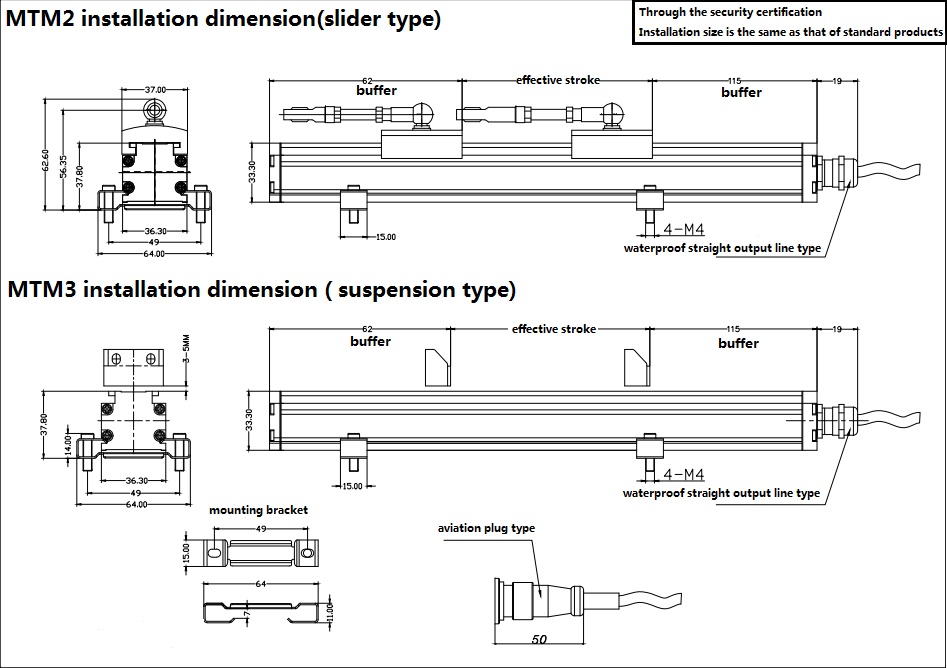

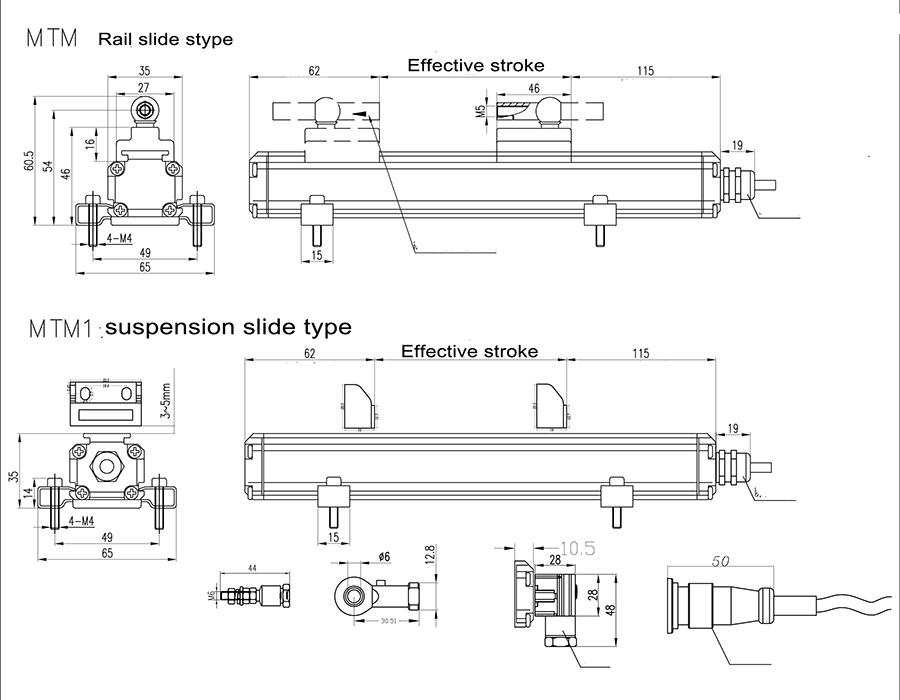

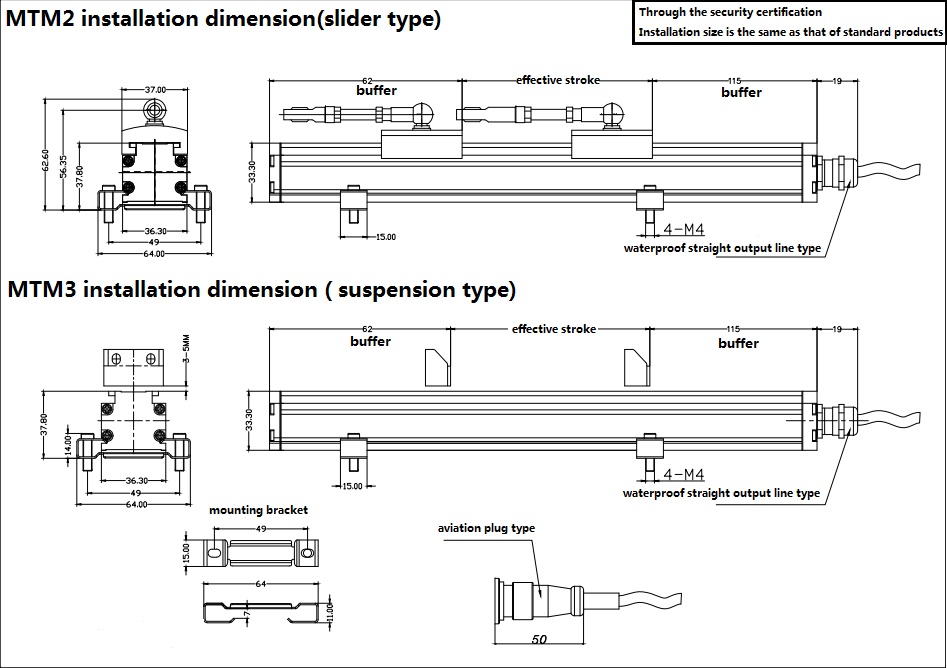

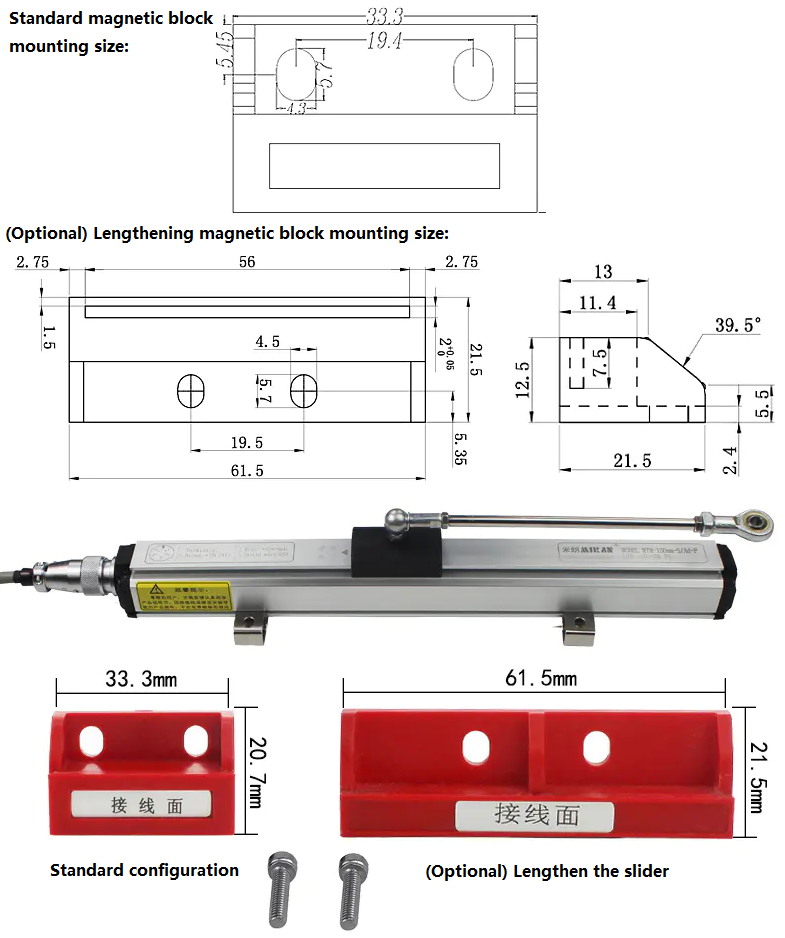

MTM Low power Guide Slide type Magnetostrictive displacement sensor Mounting size: