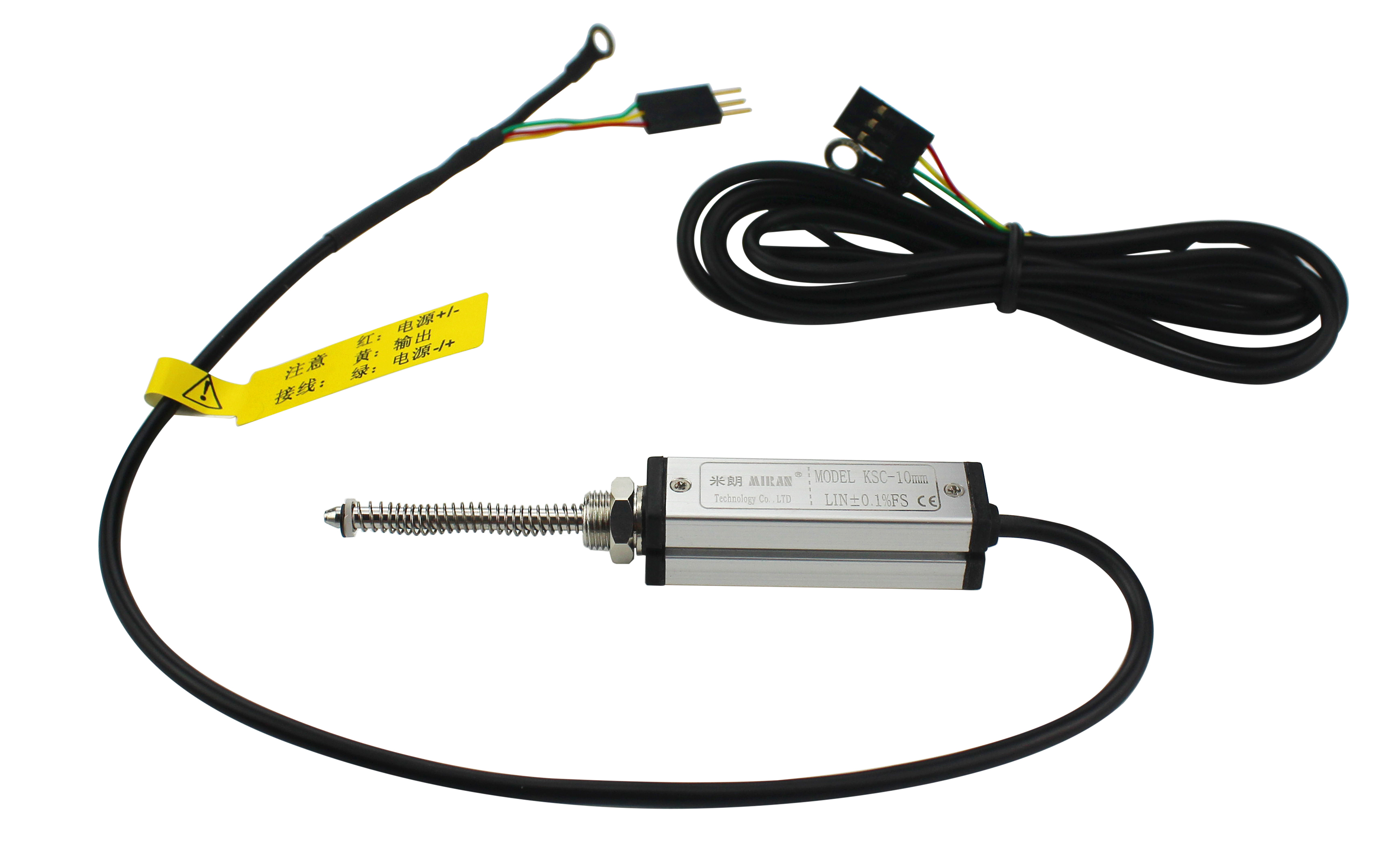

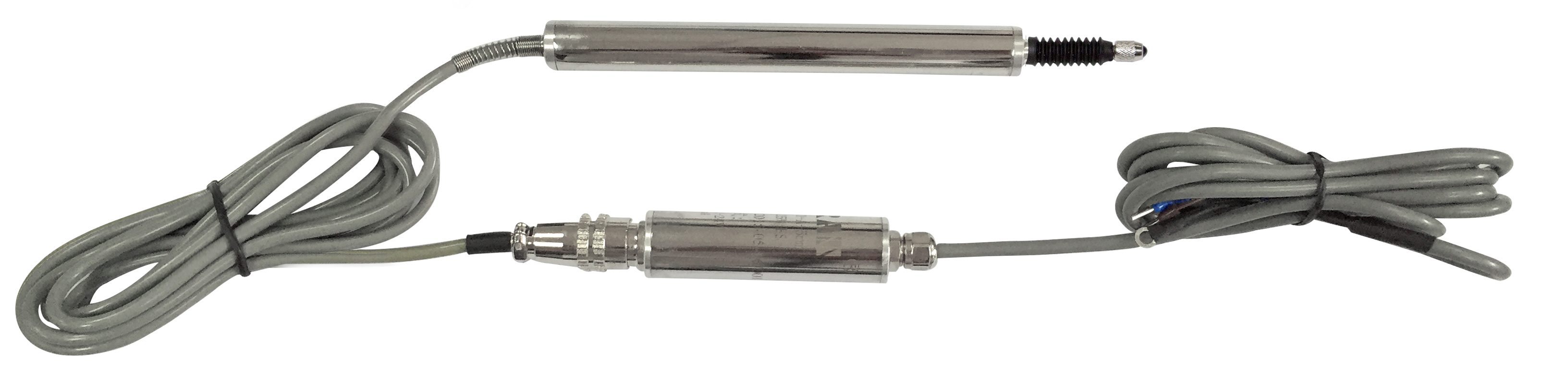

There are many types of displacement sensors, and currently the best-selling products in the market (industrial grade) include: potentiometer principle linear displacement sensors, rope type displacement sensors, magnetostrictive displacement sensors, LVDT displacement sensors, eddy current displacement sensors, grating ruler and magnetic grating ruler displacement sensors, etc. Its application scope is also very extensive, mainly in the mechanical equipment industry and the automotive field. In addition, it also has good markets in fields such as construction, transportation, metallurgy, mining, environmental protection, medical, chemical and scientific research experiments.

The mechanical equipment manufacturing and processing industry is an important component of China's economy. With the development of society, traditional mechanical equipment manufacturing technology is gradually declining, and intelligent equipment manufacturing technology, as the main force, provides a continuous stream of new impetus for the healthy development of the economy. Displacement sensors are mainly used for displacement measurement and position positioning in intelligent mechanical equipment; It is also possible to indicate the degree through online monitoring, such as monitoring the vibration, differential expansion or eccentricity performance of LVDT displacement sensors and eddy current sensors in special mechanical equipment. When abnormal conditions occur in the equipment, early warning can be given and transmitted to the control system for corresponding related operations; It can also be used as a limit sensor, speed or acceleration measurement, counter, etc.

Displacement sensors are an indispensable part of automated mechanical equipment control systems, and the performance of sensors directly determines the effectiveness of equipment control. The most classic application is the application of displacement sensors in electro-hydraulic servo control systems. Through built-in or external displacement sensors, the piston position of the hydraulic cylinder can be detected in real time, converted into proportional electrical signals and fed back to the control system. After system correction and calculation, it is transmitted to the device driver and actuator to complete closed-loop control operations.

Application of displacement sensors in the automotive manufacturing industry

The automotive industry is a special industry with a high degree of intelligence and integration. The application of sensor technology in this field has been innovative for a long time, and various miniaturized, multifunctional, integrated, and intelligent sensors are indispensable and important spare parts for automobiles or automotive processing equipment.

The main application of displacement sensors in the automotive field is to detect the size of automotive components and position them during assembly. In order to meet the high-precision detection needs of the automotive industry, high-precision sensors such as LVDT displacement sensors have been widely used in various position detection in automated production such as automotive component processing, engine manufacturing, stamping, painting, welding, and final assembly in whole vehicle factories.

Application of displacement sensors in electronic manufacturing industry

The popularization of consumer electronics products has led to rapid development of the electronic manufacturing industry. In electronic manufacturing production lines, whether it is automated production lines, industrial robots, or online and offline detection of electronic components, the participation of displacement sensors is often required. The advancement of sensor technology has directly promoted the continuous updating of mechanical equipment in the electronic manufacturing industry, and the application of more efficient, high yield, and high safety intelligent devices in the electronic industry has comprehensively improved the overall production capacity and efficiency of the industry.

Application of displacement sensors in industrial robots

The improvement of industrial robot performance and the reduction of manufacturing costs have made modern enterprise machine replacement a trend. Industrial robots often require the integration of a large number of displacement sensors, angle sensors, force sensors, proximity sensors, etc., to improve the robot's environmental adaptability and operational accuracy. In order to ensure the safety of workers, industrial robots also need to install safety sensors. When the robot senses abnormal conditions, it can trigger an emergency stop to ensure the personal safety of workers.