LEP Product Introduction:

The LEP brushless waterproof and dustproof displacement sensor is composed of two carbon film substrates, with a hollow separation between the two. On the carbon film substrate, advanced technology and process of screen printing are used to process conductive materials for potentiometers. The collection carbon film foil directly above the substrate is printed with low resistance collection sensing materials; The external force applied by the external position contact makes the sensing material of the collection membrane come into contact with the conductive material of the potentiometer, thereby generating real-time displacement signals. The dedicated screen printing coating and several continuous linear lithography processes of the lithography machine can ensure excellent linear accuracy and long lifespan of the sensor.

LEP Features:

● Flat carrier, long service life, high resolution, high stability, and excellent materials

● Prevent the intrusion of stains, dust, and liquids

● Excellent linearity, up to ± 0.05% FS

● The shell is made of hard anodized aluminum oxide, which is beautiful and elegant. The protection level is IP67, and the working temperature is high

LEP Application Field:

Medical equipment specific, robot system, valve actuator, solar panel position control, car and truck adjustment, window lifting, folding convertible roof, mirror system, etc.

LEP Standard Technical Parameters

Attention: The linearity, service life, and other values listed in the following data table indicate that the sensor operates with an operational amplifier as the voltage output to the sliding brush, and the sliding brush is not loaded (le ≤ 10) μ A) Derived from the conditions.

LEP Series | 50mm~200mm | 250mm~450mm | 500mm | Range selection reference: 50mm 100mm 150mm 200mm 250mm 300mm 350mm 400mm 450mm 500mm | |

Electrical parameters | independent linearity(±%FS) | 0.1 | 0.05 | 0.05 | |

Resistance tolerance±10% | 5.0KΩ | ||||

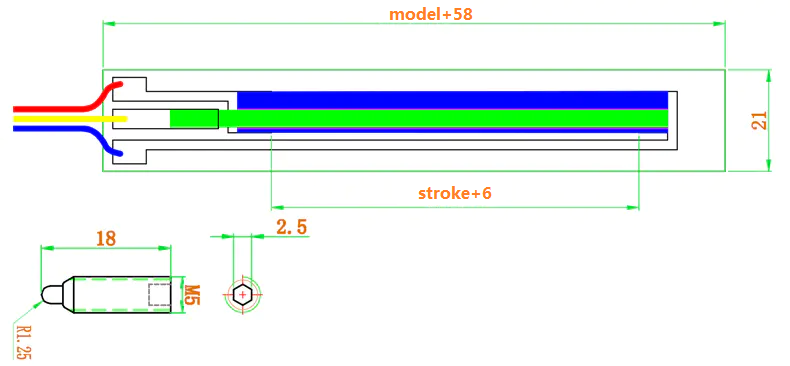

Electrical stroke | stroke+6mm | ||||

Resolution | Uninterrupted parsing | ||||

repeatability | 0.05mm | ||||

Normal working current of the sliding brush | ≤10μA | ||||

The high current of the sliding brush during the fault | 10mA | ||||

Maximum allowable working voltage | 30V | ||||

The effective temperature coefficient ratio of output voltage to input voltage | Usually 5ppm/K | ||||

Insulation impedance(500VDC) | ≥10MΩ | ||||

Dielectric Strength(500VAC,50Hz) | ≤100μA | ||||

Mechanical Parameters | width | 21.3±0.5mm | |||

Thickness | 1.3±0.2mm | ||||

Position contact | M5 Spring buffer ball | ||||

Position contact buffering pressure | 2±1N | ||||

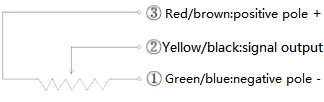

Electrical connections | 150mm Excluding connector wires and DuPont plugs, special connection methods can be customized according to customer requirements | ||||

环境参数 | Anti vibration standard | 5~2000Hz ,Amax=0.8mm ,Amax=20g | |||

Impact resistance standard | 50g,11ms | ||||

Working temperature | -40℃~+125℃ | ||||

Life | >25*106 | ||||

Maximum operating speed | 1.1m/s | ||||

IP | IP67(Excluding joints) | ||||

installation | Optional adhesive for sticking carbon film substrate back | ||||

LEP Electrical Connection:

LEP Install Dimension: