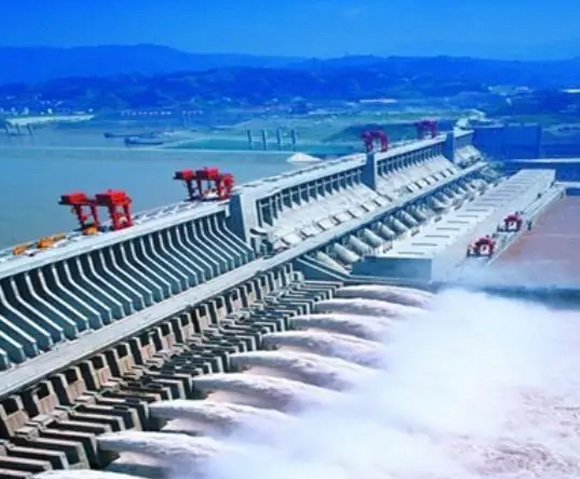

Magnetostrictive liquid level sensor is a precision position measurement device based on the principle of magnetostriction. The principle of magnetostrictive liquid level sensor is to generate a strain pulse signal when two different magnetic fields intersect, and then calculate the time period required for this signal to be detected, thereby converting the accurate position. These two magnetic fields are one from the permanent magnet in the magnetic ring and the other from the excitation pulses generated by the electronic components in the sensor's electronic compartment. The excitation pulse runs at the speed of sound along the waveguide wire made of magnetostrictive material inside the sensor. When intersecting with the permanent magnetic field in the magnetic ring, due to the magnetostriction phenomenon, the mechanical vibration generated by the waveguide wire forms a strain pulse. The strain pulse is quickly detected by the sensing circuit in the electronic compartment. The magnetostrictive liquid level sensor can accurately calculate the position change of the magnet by multiplying the total time from the moment the excitation pulse is generated to the moment the strain pulse is detected by a fixed speed of sound. This process is continuous, so whenever the position of the magnetic ring changes, the new position will be quickly measured. Due to the fact that the output signal is a true value rather than a proportional or signal that needs to be further amplified, there is no signal drift or variation, and there is no need for periodic recalibration like other sensors. Suitable for various liquid measurement and control scenarios, including liquid level monitoring of reservoir dams. The high-precision measurement capability of magnetostrictive liquid level sensors makes them an ideal choice for monitoring the liquid level height of reservoir dams. By accurately measuring the liquid level height, abnormal conditions of the dam, such as seepage and cracks, can be detected in a timely manner, and corresponding measures can be taken for repair and maintenance.

The main advantages of magnetostrictive liquid level sensors in dam liquid level monitoring include:

1. High precision measurement: The magnetostrictive liquid level sensor has extremely high measurement accuracy and can accurately reflect small changes in the dam liquid level.

2. Non contact measurement: Secondly, the magnetostrictive liquid level sensor adopts a non-contact measurement mode, which means that there is no direct contact between the sensor and the measured object, thus avoiding errors and damage caused by friction. This non-contact measurement method not only improves the accuracy of measurement, but also extends the service life of the sensor. Therefore, compared to traditional sensors, it has advantages in reliability and safety.

3. Long term stability: The magnetostrictive liquid level sensor has good stability and can operate stably for a long time without being affected by environmental interference.

4. Easy to install and maintain: The magnetostrictive liquid level sensor is easy to install, has low maintenance costs, and does not require regular calibration and frequent maintenance by personnel.

In practical applications, magnetostrictive liquid level sensors can be combined with data acquisition systems, data processing systems, etc. to achieve automated and intelligent liquid level monitoring. By analyzing monitoring data, abnormal conditions of the dam can be detected in a timely manner, providing reliable guarantees for the safe operation of the dam. In summary, magnetostrictive liquid level sensors have advantages in high-precision, non-contact measurement, long-term stability, and easy installation and maintenance in dam liquid level monitoring, providing reliable technical support for dam safety monitoring.