I. Overview of LVDT8 micro transmitter displacement sensor:

Differential transformer displacement sensors (LVDT) can be widely used in crack measurement and monitoring, bridge measurement and monitoring, aerospace, machinery, construction, textiles, railways, coal, metallurgy, plastics, chemical engineering, and scientific research institutions in various industries of the national economy. They are used to measure high-tech products such as elongation, vibration, object thickness, and expansion.

![1704696602386416.jpg 1699951372192310[1].jpg](/uploads/image/20240108/1704696602386416.jpg)

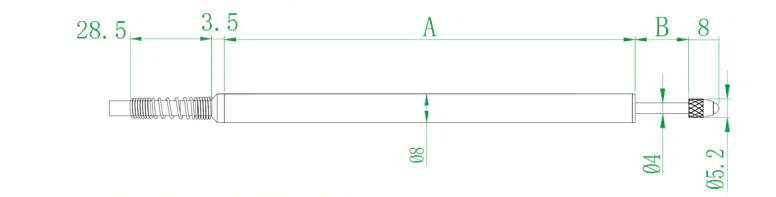

LVDT8 buckle mounted displacement sensor has excellent performance and is suitable for high-precision and high repeatability measurements in quality control and metrology applications. The measuring head adopts high hardness wear-resistant material silicon nitride ceramic, and the moving part of the measuring shaft adopts a precision guide rail. The pen displacement sensor is equipped with an external transmitter that can output standard DC signals. It uses a convenient single power supply+12-30V DC power supply, and the electronic circuit is sealed in a 304 stainless steel metal tube, which can work in harsh environments such as humidity and dust. The output signal is a standard 0-5V, 0-10V, 4-20mA or RS485 output that can be used by computers or PLC.

![1704768322807385.jpg 1704697944751259[1].jpg](/uploads/image/20240109/1704768322807385.jpg)

II. Characteristics of LVDT8 micro transmitter displacement sensor:

1. Outer diameter Φ 8mm pen shaped rebound displacement sensor

2. The probe is made of silicon nitride ceramic balls, which have good wear resistance

3. The measurement range is from 0-10MM, with high resolution and good repeatability

4. No sliding contacts, long service life

5. Power supply for AC signal, equipped with high-performance signal demodulator externally

6. Two wire 4-20mA current output, three wire 0-5V or 0-10V voltage output, and four wire RS485 signal output.

III. Application fields of LVDT8 micro transmitter displacement sensor:

Axial runout detection, textile machinery detection, valve position detection and control, roller gap measurement, vehicle brake device wear measurement, robot and precision displacement measurement, online detection of automotive parts, machine tool and tool positioning, hydraulic cylinder positioning, bridge displacement detection, subway tunnel engineering protection

IV. Technical parameters of LVDT8 micro transmitter displacement sensor:

Stroke Length | 2.5mm,5mm,10mm |

Output Signal | 0~5V, 0~10V,4~20mA,RS485 |

Resolution | ≤0.1um, Digital output is 16bit |

linearity Error | ≤±0.25%FS |

repeatability error | 1um |

Power Supply | +12~30V DC |

Working Current | Voltage Output: <10mA |

4-20mA Output: 4~25mA | |

RS485 Output: 15~40mA | |

Dynamic Characteristics | 10Hz |

Shock Resistance | 250g/11ms |

Vibration Tolerance | 10g/2KHZ |

Excitation Voltage | 3Vrms |

Excitation Frequency | 5KHZ |

Temperature Coefficient | Zero Point≤0.01%/℃ |

Sensitivity | ≤0.025%/℃ |

Operation temperature | -25℃~+85℃ |

Selection guidance:

![1704778036229517.jpg 1704702737693043[1].jpg](/uploads/image/20240109/1704778036229517.jpg)

Wiring method:

Attention!!! The sensor pen and transmitter must be used together (with the same pen number as the transmitter number), and it is prohibited to exchange them randomly, otherwise the linear accuracy of the sensor will be severely distorted

1. Color definition of current signal output cable:

Brown - Power supply (+) current input (+)

Blue - Power supply (-) Current output (-)

2. Color definition of voltage signal output cable:

Brown - Power supply (+)

Blue - Voltage output (+)

Black - Power supply (-) Signal output (-)

3. Color definition of digital RS485 signal output cable:

Brown - Power supply (+)

Black - Power supply (-)

Blue - Signal A

White - Signal B

V. Installation dimensions of LVDT8 micro transmitter displacement sensor:

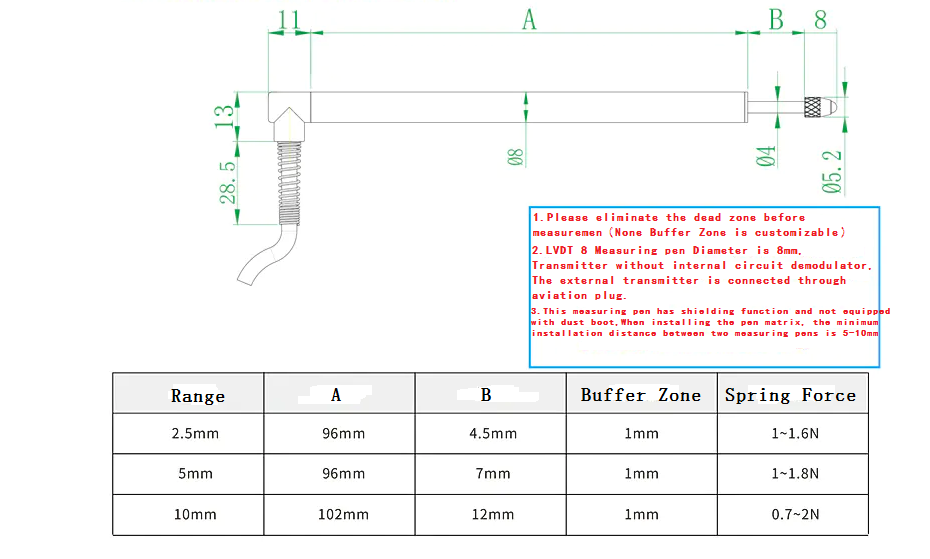

LVDT8 tail straight line (without dust cover)

LVDT8 tail side line (without dust cover)

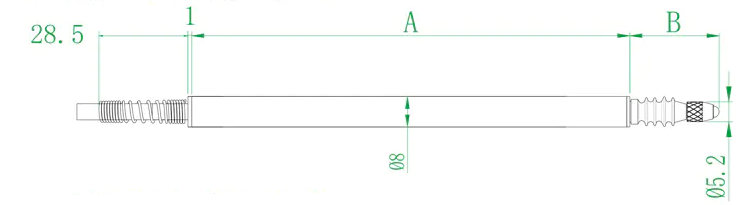

LVDT8 tail straight line (with dust cover)

LVDT8 tail side line (with dust cover)

PS: 1. LVDT8 measuring pen without dust cover has a shorter length and added shielding function, solving the problem of mutual interference between measuring pens. More suitable for matrix installation scenarios, with a minimum installation spacing of 5-10mm for measuring pens. The vulnerable parts of the measuring pen, such as the iron core and spring, can be easily replaced.

2. LVDT8 measuring pen with dust cover is more suitable for environments with dust. If matrix installation is required, the installation distance of each measuring pen should not be less than 40mm. If a smaller installation distance is required, additional shielding function needs to be customized.

![1704771078285967.jpg 1699951374903320[1].jpg](/uploads/image/20240109/1704771078285967.jpg)

![1704771470144640.jpg 1699951374931808[1].jpg](/uploads/image/20240109/1704771470144640.jpg)