Injection molding is a cyclic process, each cycle mainly includes: quantitative feeding - melt plasticization - mold locking - injection stage - positive pressure injection molding - cooling - injection stage - post opening - product spraying, removing the molded part, and then closing the mold for the next cycle. In this cycle, it is necessary to control the locking of the mold, injection table, injection molding, and product ejection. The injection molding and locking clamping stroke control of the vertical injection molding machine play a decisive role in the performance and product accuracy of the injection molding machine. This process is completed by displacement sensors for position feedback, positioning, and closed-loop control functions. For example, the opening/closing action must be quickly and accurately executed, the positioning of squeezing and blowing film must be accurate, and the locking and ejection travel must be fully monitored.

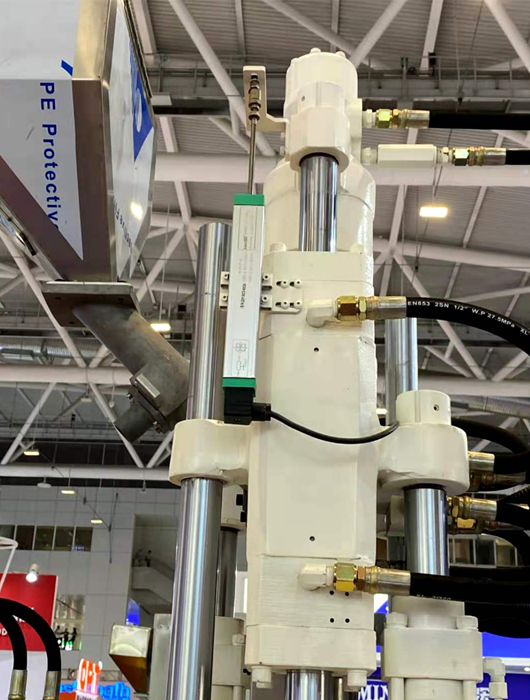

Specifically, the pull rod displacement sensor can monitor the position and movement of the mold in real-time, ensuring that the injection table can reach the designated position during the movement process, thereby achieving injection molding operations. At the same time, the sensor can also monitor the opening and closing of the mold, ensuring that the product can be smoothly ejected from the mold after cooling and solidification.

Overall, the application of rod displacement sensors in vertical injection molding machines provides reliable technical support for the control and efficient production of injection molding machines through their measurement and monitoring capabilities.