Ⅰ、Overview of ultrasonic displacement sensor

Ultrasonic displacement sensor is a kind of mechanical wave whose vibration frequency is higher than that of sound wave. It is developed by using the characteristics of ultrasonic wave and vibrated by energy exchange wafer under the excitation of voltage. It has the characteristics of high frequency, short wavelength, small diffraction phenomenon, especially good directivity, can become a ray and directional propagation.

Ultrasonic displacement sensor ranging generally uses TOF (Time of Flight). Distance between ultrasonic displacement sensor and obstacle S=vt/2. According to the principle of time of flight between ultrasonic transmission and reception, the acoustic medium is used for non-contact non-wear detection of the detected objects, transparent or non-ferrous objects, metal or non-metallic objects, solid, liquid, powder substances can be detected. Its detection performance is not affected by workpiece color, material, transparency, including dust environment and rainy days. Can be widely used in level (liquid level) monitoring, robot collision prevention, all kinds of ultrasonic proximity switches, as well as anti-theft alarm and other related fields, reliable work, easy installation, waterproof type, launch Angle is small, high sensitivity, convenient and industrial display instrument connection.

Ⅱ、Ultrasonic displacement sensor application field

Distance measurement, level measurement, height measurement, interval measurement, size measurement, material accumulation height measurement, filling level measurement, filling liquid level detection, diameter and velocity measurement, contour measurement, tension control, packaging detection, object counting, etc.

Ⅲ、Ultrasonic displacement sensor technical parameters

Product model | MCSB-A series |

Measuring range | 70~1070mm |

Dead zone | 70mm |

Response time | About 100ms |

Resolution | 0.13mm(max) |

Standard test plate | 300x300mm |

Beam angle | 10~15° |

Accuracy | 0.1% |

Transducer frequency | 200KHz |

Working voltage | 15~30VDC |

Ripple voltage | 5% |

Working current | 20mA |

Output mode | 0-5V、0-10V、4-20mA、RS485 |

Working temperature | -20°C~+60°C |

Storage temperature | -40°C~+70°C |

Protection | IP67 |

Housing material | nickel plated brass |

Line length | 2m |

Indicator meaning | Yellow light:The yellow light is unchanged and the object is within the measuring range. |

Indicator meaning | Red light:If the indicator is steady red,power on.Long dark,wrong. |

Ⅳ、Ultrasonic Displacement Sensor Selection Guidance

Ⅴ、Ultrasonic Displacement Sensor Installation Size

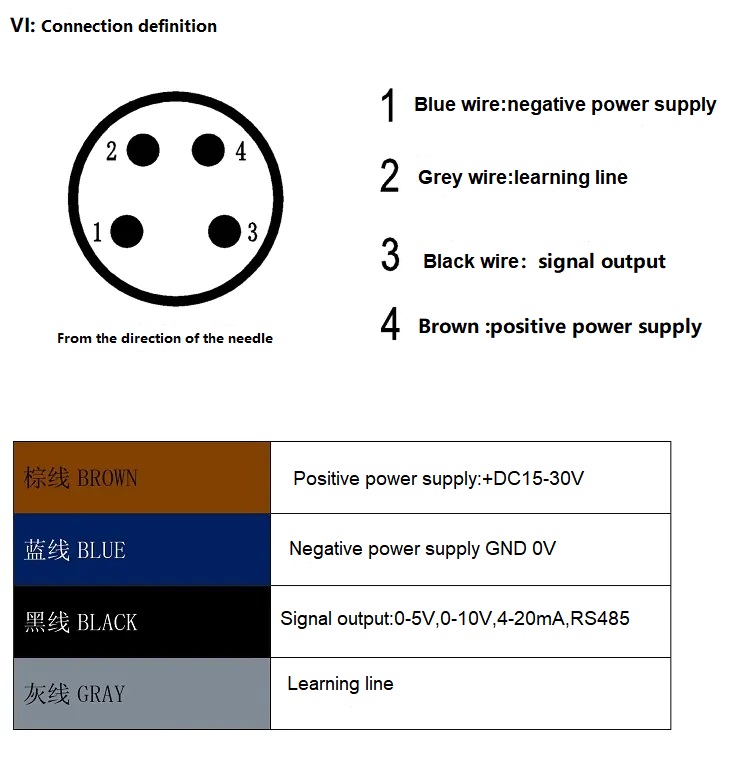

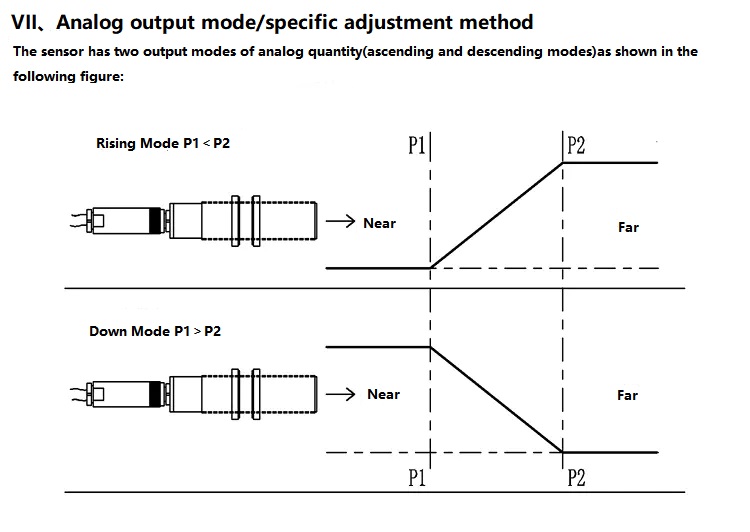

The specific adjustment methods are as follows:

First, the sensor is powered on, and the red and yellow indicators on the back of the sensor will light up.

Set the longer distance P2:

Place an object under test where you want to set the distance. Connect the gray wire (learning wire) and brown wire (power supply positive) together. During this period, if the object under test is captured, the yellow light will keep flashing. After this state lasts for four to five seconds, remove the gray wire. Setup successful.

Set the closer distance P1:

Place an object under test where you want to set the distance. Please connect the gray wire (learning wire) and blue wire (negative power supply). During this period, if the object under test is captured, the yellow light will keep flashing. After this state lasts for four to five seconds, remove the gray wire. Setup successful.

Note: During the setting process, the yellow light and the red light may flash together, indicating that the sensor does not accurately capture the object being measured. The sensor needs to be moved slightly to align it with the object being measured. Until the yellow light flashes continuously alone. This setting process must be completed within 3 minutes, otherwise the sensor will be locked. It is necessary to disconnect the power supply and re-power it, and then reset it.

Ⅷ、Ultrasonic displacement sensor installation instructions

Since ultrasonic sensors are directional, be sure to pay attention to their installation location. It is recommended that the installation position be perpendicular to the object being measured, so that the measurement data will be relatively accurate. (Comes with mounting fixing nuts)

Ⅸ、Precautions for ultrasonic displacement sensor

● The sensor is a precision instrument, please do not scratch the surface.

● The sensor cannot be used in vacuum areas or explosion-proof areas.

● Make sure the sensor's supply voltage and ripple voltage are within specifications.

● Do not use the sensor near water, steam, acid or solvent above 50℃.

● When using the sensor, there should be no strong mechanical vibration, and the working environment should not have strong electromagnetic interference.